MACHINING

> PROGRAMS > CAREER & TECHNICAL EDUCATION > INDUSTRIAL & ENGINEERING TECHNOLOGY PROGRAMS > MACHINING

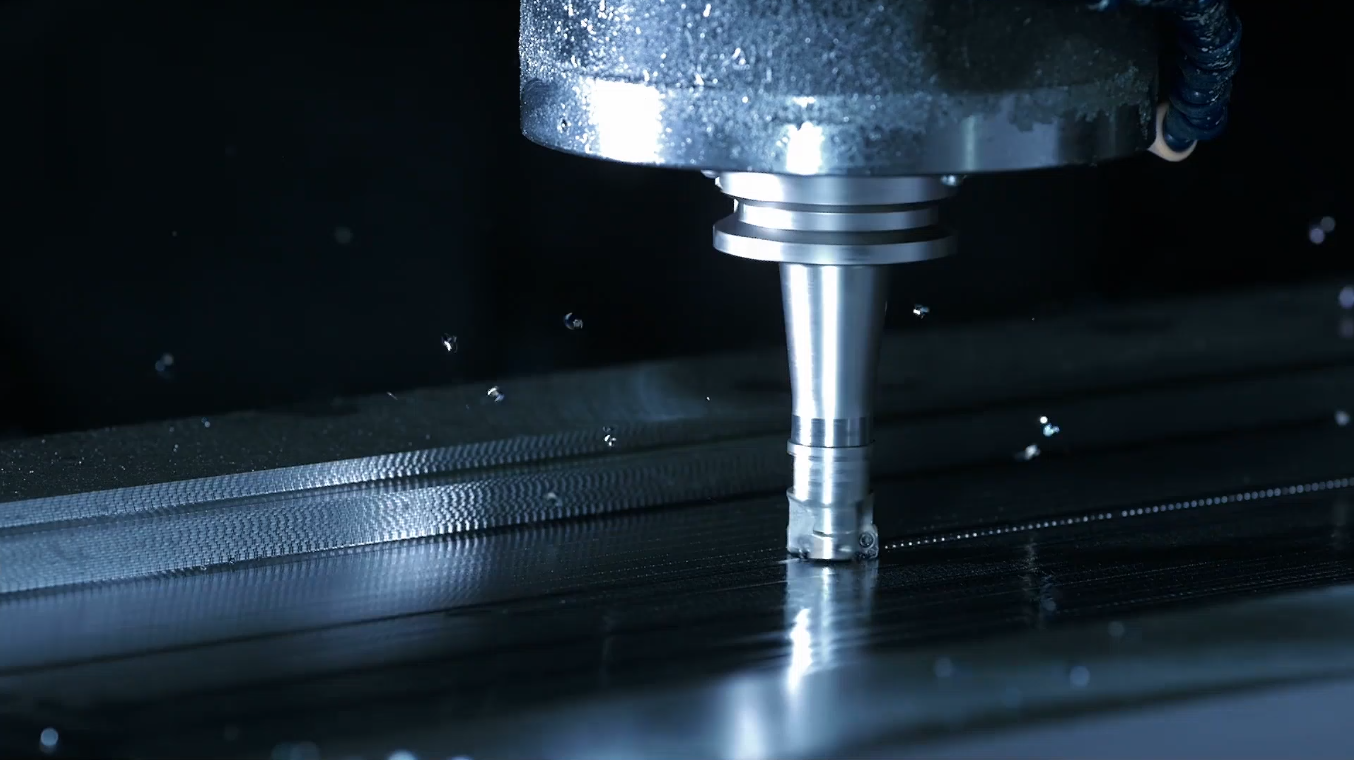

NCTC’s Machining Technology program prepares students for careers in manufacturing, oil and gas, and even aerospace. Machinists work in manufacturing, construction, or specialized shops using machine tools to make or modify parts, primarily made of metal. While machinists in our program will learn various foundational welding techniques, their studies will also include operation of computer numeric control (CNC) equipment, more traditional tool and die mechanical machinery, mathematical applications, and more.

Machining Degrees & Certificates

The Machining Technology program is designed to prepare students for a career as a machinist. Machinists typically work in manufacturing, construction, or specialized shops. Students who complete the Machining Technology program at NCTC are prepared to start an exciting career with continued and expected growth.

Machining Basic Certificate

This certificate can be completed with a combination of online, hybrid, and face-to-face classes. The program is designed to be completed in one semester, or 16 weeks and consists of the following course of study.

Machining Technology Certificate

This certificate can be completed through a mix of face-to-face, hybrid, and online classes. The program is designed to take one year, or 42 weeks, to complete and consists of the following courses.

Machining Technology AAS

This degree can be completed through a mix of face-to-face, hybrid and online classes. The program is designed to take two years to complete and consists of the following courses.

Career Outlook

Machinist: Responsible for installing and operating a wide range of tools to create precision parts and instruments from metal. They may fabricate and modify pieces and parts to upkeep the maintenance of industrial equipment, and are also knowledgeable in mechanics, mathematics, metal properties and mechanical procedures.

Tool & Die Maker: Work on verifying dimensions, alignments, and clearances on finished products to ensure maximum performance and that all standards are adequately met. They lay out metal, set up and operate machine tools, fit and assemble parts and make any necessary adjustments to dies, cutting tools, gauges, and so forth to guarantee optimal performance.